Add to Cart

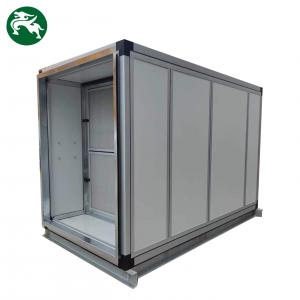

Low Noise 1500CMH Pure Water Heat Recovery Heating Air Handling Unit

Longer Leader air heat recovery AHU’s air flow range is from 1,000m3/h to 300,000m3/h. Heat recovery unit is the part or module of air handling unit that incorporates the heat exchanger and its auxiliary equipment(motor, controls ect), but is often used to descrive the whole packaged AHU incorporating its heat exchange.

Longer Leader has 4 kinds of heat recovery parts as belows,

Features: After the air is cooled by the evaporator, the temperature is very low. It's extremely energy consuming to add an auxiliary electric heating to raise the temperature. If using the heat of condensation instead of electric heating, it will not only reduce the risk of fire potential, but also save a lot of electricity.

Features: Since it is phase change heat transfer and the internal thermal resistance of the heat pipe is very small, a large heat transfer amount can be obtained under a small temperature difference. The cross-contamination and leakage rate of fresh air and exhaust air is ≤1%. The heat recovery efficiency is usually 50%, and the device requires no power.

Heat pipe heat recovery uses heat pipe elements as energy recovery cores to exchange energy with the passing fresh air and exhaust air, thereby realizing energy recovery and utilization. Heat pipes are composed of closed vacuum metal tubes filled with a certain amount of refrigerant. Heat pipe heat recovery used in civil building ventilation and air conditioning generally adopts the form of gravity heat pipes.

Working principle: When the hot end (evaporation section) of the gravity heat pipe absorbs heat from the hot air flow flowing through the heat pipe, the volatile liquid in the heat pipe evaporates, and the highly saturated vapor generated flows to the cold end (condensation section), and the cold air flow absorbs the vapor. The released condensation heat is then condensed into liquid and flows back to the evaporation section by gravity, thus continuously exchanging heat.

Features: The cross-contamination and leakage rate of fresh air and exhaust air is ≤5%, the heat recovery efficiency is usually about 65%, and the device does not require power.

Working principle: Depending on the temperature or humidity difference in the air (fresh air and exhaust air) flowing through both sides of the board, when the fresh air and exhaust air flow through the closed two-side panels in a cross or counter-flow form, energy exchange will occur on both sides. exchange.

Variable speed drive (VSD) technology, explosion proof and energy saving.