Add to Cart

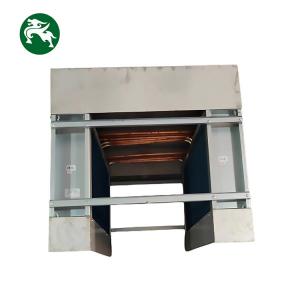

U-Shaped Wrap-Around Heat Pipe Energy Recovery Air Heat Exchanger Use For Data Center

Heat pipe could transfer heat with minimal temperature differences between one end and the other.

Passive heat pipe do not need a circulating pump to operate and have no operating cost except for a nominal increase in static pressure. They have no moving parts to malfunction or to be maintained.

There are many applications for the company’s patented technology. Commercial markets are extremely receptive to the dehumidification products and heat recovery products. The major market moves to health care, education and data centers application.

Recent Heat Pipes for Dehumidification & Energy Recovery

In HVAC system, the colder the air becomes as it passes through the cooling coil, the more moisture condenses out. Longer leader heat pipes

are wrapped around the cooling coil, with one part of the heat pipe being in the return air flow and another part of the supply air flow. The warm incoming air is precooled by the evaporator (precooling) portion of the heat pipe. The air is then passed through a cooler to further cool (subcool) the coils to extract more moisture. Next, the air is passively heated by the condenser (reheating) portion of the heat pipe to reduce the relative humidity. The air exhausted from the heat pipe system now has a much lower moisture content and a lower relative humidity.

Without consuming energy, in addition to a small increase in static pressure, the heat pipe pre-cooling effect enables the cooling coil to operate at a lower temperature, thereby greatly improving the dehumidification capacity of the system. When humidity is lower, indoor air becomes more comfortable with a higher thermostat setting, resulting in net energy savings.

Heat pipes are also used to recover energy and act as heat exchangers between supply and exhaust air streams. With no moving parts and no need for a tilting mechanism, Longer Leader energy recovery modules have clear advantages over competitors and other technologies.

In summer, the fresh air passes through the evaporation section of the straight plate heat pipe and the condensation end of the indoor return air straight plate heat pipe for cold recovery.

In winter, the fresh air passes through the condensation end of the straight plate heat pipe and the evaporation end of the indoor return air straight plate heat pipe for heat recovery to achieve an energy-saving recovery device.

Variable speed drive (VSD) technology, explosion proof and energy saving.